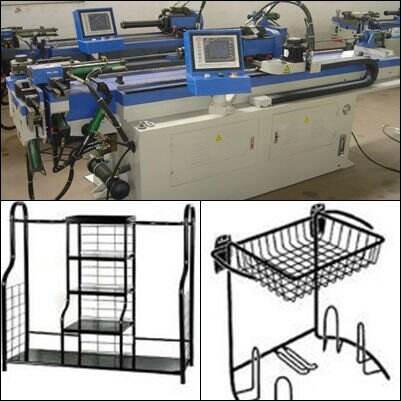

Hydraulic NC Pipe Bending Machine GM-SB-38NCB

Full hydraulic drove, PLC controlled with touch screen or text pipe bending machine, equipped with devices of pipe clamping, guide Mould, mandrel, crease-resistant, assist pushing, pipe bending and so on. Under hydraulic operation, this professional, high speed and economic European pipe bending machine can bend various dimension both normal and abnormal shape metal pipes and bending angles are controlled by high precision imported encoder which ensures high precision of this machine.

Name | Unit | Parameter |

Max. Bending Capacity | mm | 38*2 |

Bending Radius Range | mm | 20-200 |

Max. Bending Angle | ° | 190° |

Bending Speed | °/sec | 60 |

Bending Precision | ° | ±0.10 |

Max feeding length | mm | 3000 |

System Motor Power | kW | 4 |

Max. Pressure | Mpa | 16 |

L*W*H (Packaging Dimension) | mm | 3200*700*1300 |

Weight | T | 1.5 |

Machine features

1. Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2. Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc

3. Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

4. About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

5. Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient

1. Q: How to choose the right type/model of the pipe/tube bending machines?

A: You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2. Q: What is the difference for NCB, NCBA and CNC machines?

A: NCB is standard hydraulic pipe bending machines, feeding and rotation are manual, and bending is hydraulic automatic.

NCBA is semi-automatic pipe bending machines, mechanical gear feeding, servo motor automatic angle rotation and hydraulic automatic bending.

CNC is fully automatic pipe bending machines, servo motor for feeding and rotations, and hydraulic or servo motor, multiple tooling stack are available for two and more different bending radius (CLR).

3. Q: What is the machine’s control?

A: Standard control is Mitsubishi PLC, Special is IPC controls. IPC with function of 3D view, 3D simulation, DWG readout, remote assistance etc.

4. Q: What is the biggest bending capacity you could offer?

A: As of now the biggest bending capacity is 325mm outside diameter for cold bending. For hot bending, the capacity would be1450mm.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou city (near to Wuxi). You can fly to Shanghai or Wuxi airport & Zhangjiagang train station.

6. Q: How is the training and after sales service?

A: Customer is welcome to visit our factory for pre-shipment, and we will provide training service FOC, or we can send our professional engineer to be abroad in customer's plant, and customer will pay for the air tickets, accommodation, meals and USD150 per day

GMACC

Looking for a reliable and efficient way to bend pipes? Look no further than the Hydraulic Pipe Bending Machine Tube Bender from this powerful and versatile machine features all the technology and materials you need to get the job done quickly and efficiently, whether you're working in a busy shop or on a construction site.

A powerful system is hydraulic GMACC enables you to easily and accurately bend steel pipes of various sizes and thicknesses. By having a range of bending angles from 0 to 180 degrees, you can easily produce the fold is perfect your specific requirements. and with a pipe is optimum of 2 inches, this tube bender is suitable for the wide range of pipe and tube sizes.

But not totally all. features a range of advanced functions to assist you get the working task done quickly and efficiently. for instance, the machine is equipped by having a readout is digital that can help you monitor the angle associated with bend, ensuring accuracy and repeatability with every job. and with a motor is effective heavy-duty steel construction, this tube bender is designed to face as much as even the toughest jobs, year in year out.

Needless to say, safety is obviously a priority is to working with heavy machinery. Packed with built-in safety features designed to keep you and your team safe while working. for example, the equipment is equipped with a security foot switch that enables you to easily and properly run the arm is bending keeping your hands free. Along with a variety of other safety features, you can trust that this pipe bender is designed with your safety in brain.

So, if you're looking for a reliable and efficient way to bend pipes and tubes, look no further than the GMACC Hydraulic Pipe Bending Machine Tube Bender. with its powerful hydraulic system, advanced features, and built-in safety features, this tube bender is the perfect solution for any job, big or small. Order yours today and experience the power and reliability of GMACC machinery.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW