GMACC

Presenting the 3 Axis auto tube/Pipe bender GM-SB-89CNC-2A-1S from GMACC. This product is made to make bending pipelines and pipes a task effortless without the need for handbook work or expertise. The GM-SB-89CNC-2A-1S is simply a must-have if you are in search of a pipe dependable for the industrial or manufacturing operations.

The 3 Axis auto tube/Pipe bender GM-SB-89CNC-2A-1Ss regarding the high-speed function bending engineered to fold pipelines and pipes quickly sufficient cause for accuracy. It boils down fashioned with a control CNC enabling anyone to plan the angle, bending radius, and bending rate without needing intervention handbook. The GMACC product is user-friendly and simple to operate, providing you with a seamless and experience hassle-free.

The equipment works well at bending pipes and pipelines of varying sizes up to 89mm diameter., its designed with a mandrel removal and insertion system that gives a smooth and performance consistent is bending. The mandrel system provides you with an assortment wide of choices, permitting exact, complex, and compound bends with simplicity.

Additionally, the 3 Axis auto tube/Pipe bender GM-SB-89CNC-2A-1S has a potent force hydraulic that gives an increased degree of effectiveness and precision. These devices provide constant and performance dependable is bending which makes it perfect for industrial and manufacturing operations that depend on the precision of the gear to provide top-quality items.

The 3 Axis car tube/Pipe bender is versatile and can be employed to fold many materials, including aluminum, copper, stainless, along with other metals. This particular feature helps it is a good investment very good organizations related to HVAC, automotive, or aerospace production.

The GM-SB-89CNC-2A-1S was created to run with reduced sound, making your environment working is and conducive to get results. Additionally, it is fashioned with security features to guard operators from any accidents possible. The product is easy to put in, run, and keep maintaining, requiring setup minimal and upkeep.

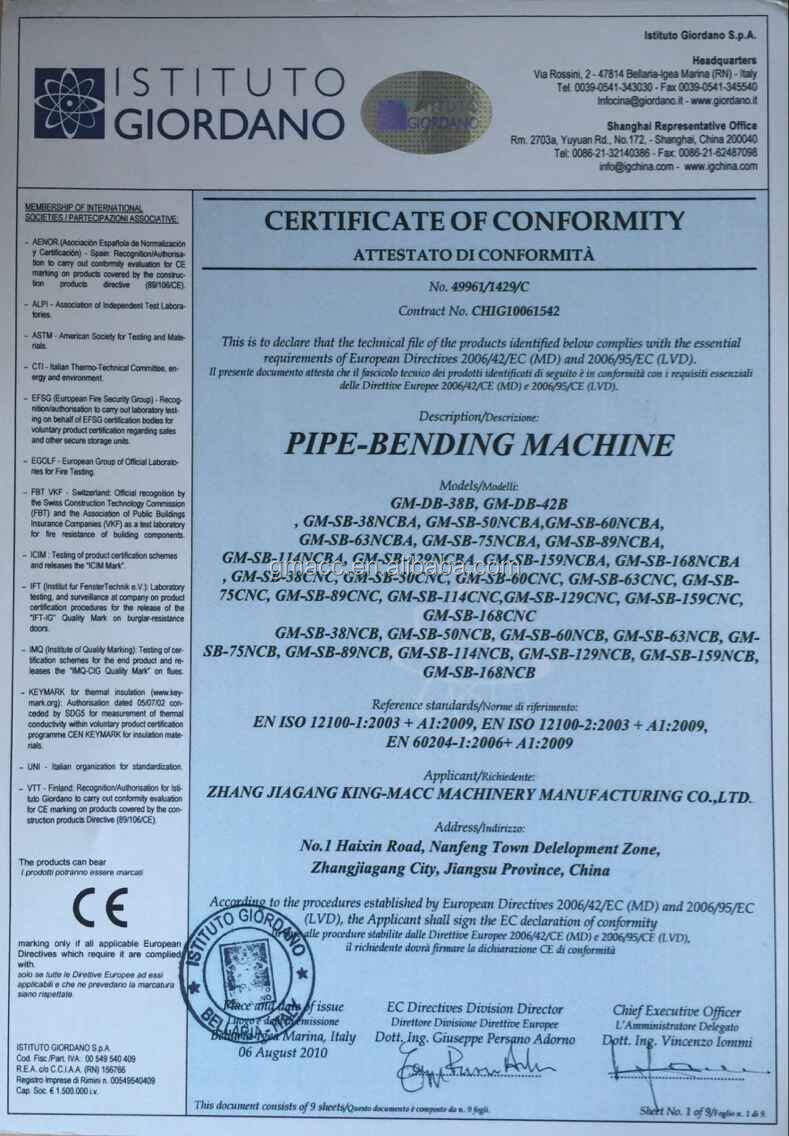

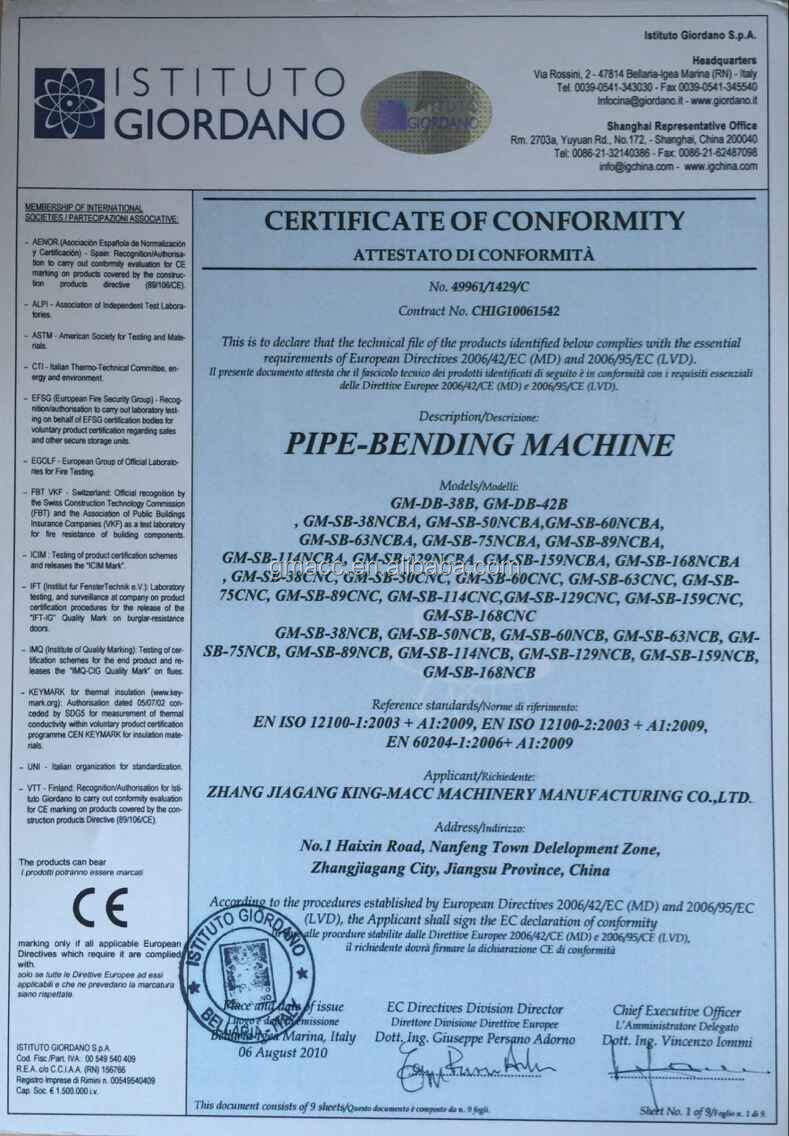

Finally, the 3 Axis auto tube/Pipe bender GM-SB-89CNC-2A-1S is supported by GMACC's dedication to quality and client satisfaction. The unit undergoes a quality rigorous procedure to make sure it satisfies the most effective requirements of quality and gratification., GMACC provides comprehensive after-sales help, including training, tech support team, and free components materials, ensuring that you receive many from the gear.

Technical Parameter and Configuration for Automatic Pipe Bending Machine GM-SB-89CNC-2A-1S

SB-CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinate so motions under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending springback compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Pipe bending(C axis), pipe rotating (B axis), and pipe feeding(Y axis) are all automatic.

|

Name

|

Unit

|

Parameter

|

|

Max. Bending Capacity

|

mm

|

89*6

|

|

Bending Radius Range

|

mm

|

40-400

|

|

Max. Bending Angle

|

°

|

190°

|

|

Bending Speed

|

°/sec

|

2800

|

|

Turning Speed

|

°/sec

|

25

|

|

Feeding Speed

|

mm/sec

|

160

|

|

Bending Precision

|

°

|

500

|

|

Turning Precision

|

°

|

±0.10

|

|

Feeding Precision

|

mm

|

±0.10

|

|

Turning Servomotor Power

|

kW

|

±0.10

|

|

Feeding Servomotor Power

|

kW

|

2

|

|

ThougEffective Distance

|

mm

|

2

|

|

System Motor Power

|

kW

|

11

|

|

Max. Pressure

|

Kg/cm

|

30

|

|

Oil Pump Delivery Volume

|

L

|

16

|

|

L*W*H (Packaging Dimension)

|

mm

|

5500*1350*1200

|

|

Weight

|

T

|

5.0

|

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW