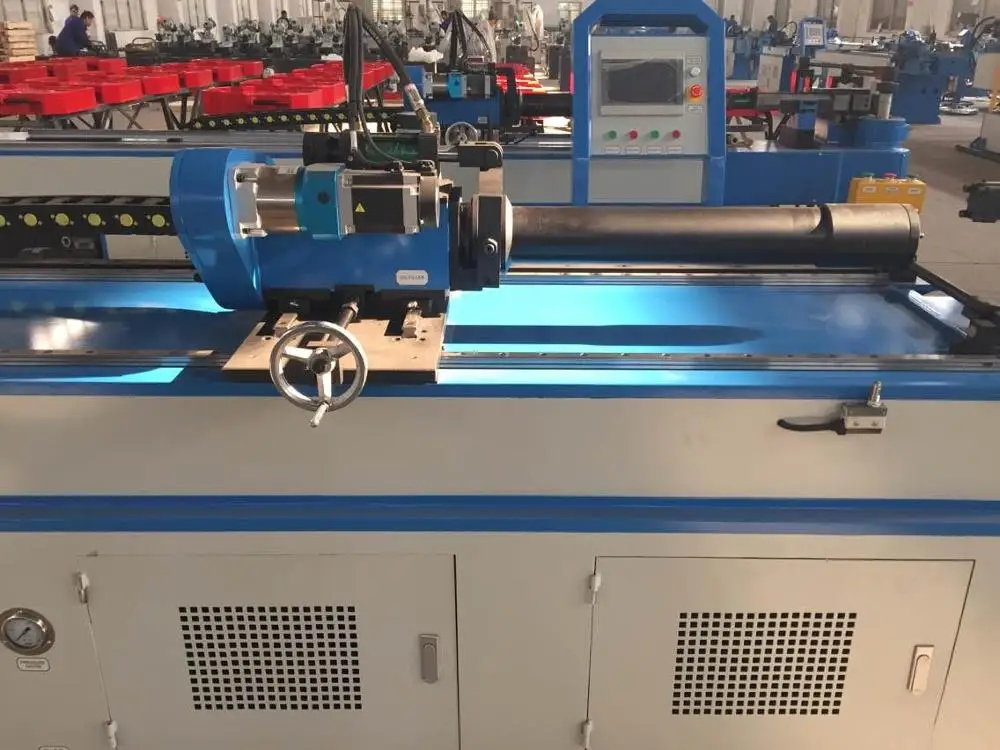

GM-SB-76CNC Full-Auto Numerical Control

Single-Head Bending Machine

Model: 76×2A×1S

Ø Machine Characteristics

GM-SB-76CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order, Y, B, C three coordinates of motions under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending spring back compensation, errors self-diagnose alarm, memory store after power off, automatic lubrication and safety protection. Pipe rotating B axis, and pipe feeding Y axis are bother driven by servo motor. Pipe bending C axis is hydraulic by cylinder

Ø Main Technical Parameter

|

Name

|

Unit

|

Parameter

|

|

Max. Bending Capacity

|

mm

|

76*5

|

|

Bending Radius Range

|

mm

|

30-350

|

|

Max. Bending Angle

|

°

|

190

|

|

Bending Speed

|

°/sec

|

30

|

|

Turning Speed

|

°/sec

|

160

|

|

Feeding Speed

|

mm/sec

|

800

|

|

Bending Precision

|

°

|

±0.10

|

|

Turning Precision

|

°

|

±0.10

|

|

Feeding Precision

|

mm

|

±0.10

|

|

Turning Servomotor Power

|

kW

|

1

|

|

Feeding Servomotor Power

|

kW

|

1.5

|

|

Though Effective Distance

|

mm

|

4000

|

|

System Motor Power

|

kW

|

7.5

|

|

Max. Pressure

|

Mpa

|

16

|

|

Oil Pump Delivery Volume

|

L

|

25

|

|

L*W*H Packaging Dimension

|

mm

|

5300*1300*1500

|

|

Weight

|

T

|

3.5

|

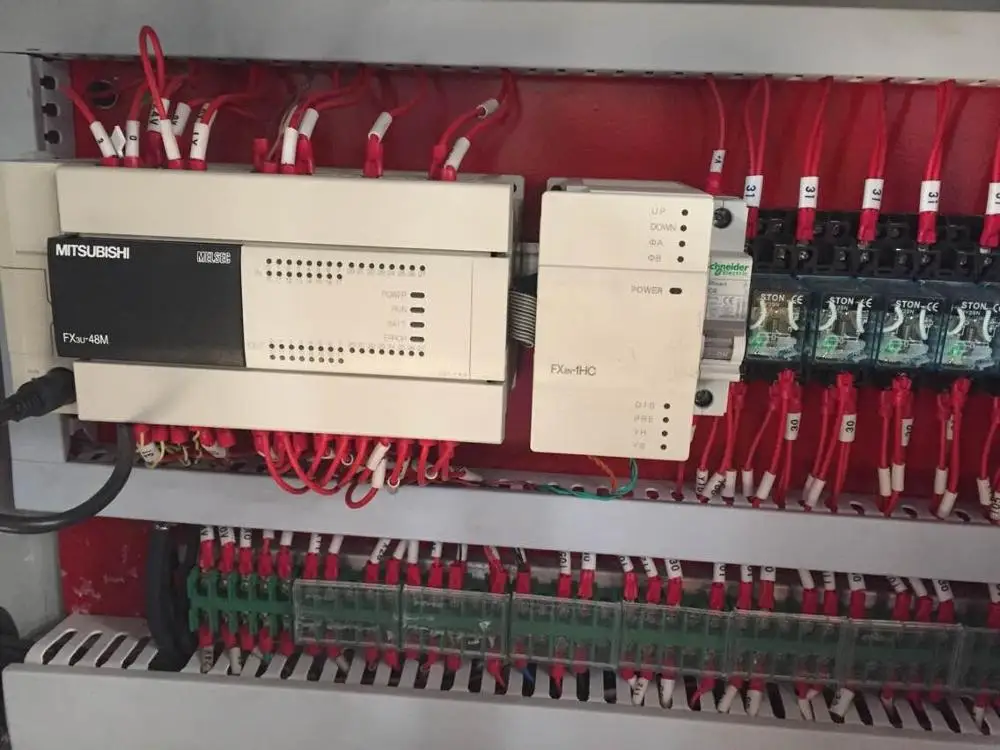

Ø Configuration of Hydraulic and Electronic Control System

|

Name

|

Manufacturer

|

|

Hydraulic Motor

|

Suzhou Runmali

|

|

Hydraulic Pump

|

Wuxi Tuoli

|

|

Hydraulic Valve

|

Japan Yuken

|

|

Oil way Board

|

Suzhou Boguan

|

|

Cylinder

|

Shanghai Qifan

|

|

Oil tube

|

Suzhou Kejia

|

|

Touch screen

|

Taiwan Weinview

|

|

PLC

|

Japan Mitsubishi

|

|

Servo Motor

|

Japan Mitsubishi

|

|

Angle controller

|

Japan Nemicon

|

|

Switch power

|

Wenzhou Changxing

|

Our Services

1) Observing &Testing

After we receipt 30% advance deposit, we will start to produce. When the machine is completed, buyers come to observe and test machine by themselves, until the machine is satisfied with the buyers, they can pay for the other 70% balance

2) Technical documents

The seller should supply buyer the documents for installation and commissioning within 5 days after contract is available, other related documents will be supplied to buyer before shipment

3) After-sale service

After sale service shall be done by the seller. Seller will provide all kinds of technical support to the buyer by telephone, fax or email free of charge. After one-year guarantee period, we assure you life-long maintenance

4) Installation

We provide electrical control maps and instruction book to you for installation with English instruction. If required, we can send 1 or 2 engineers to buyer’s country for installation and training

GMACC

CNC bending is complete hydraulic could be the solution this most appropriate for companies that need efficient and accurate metal bending. Designed to handle materials have become simpleness is different.

Offer precise and outcomes time is constant. This system employs power sources are metals hydraulic fold rendering it effective and dependable. These devices furthermore carries a control is CNC rendering it and task that's not plan run is hard.

One of the primary advantages is its freedom. It might probably flex an array of materials, including steel is stainless aluminum, and copper. The apparatus can do doing various perspectives being radius is bending having an angle bending that maximum of. This enables businesses to make a variety is proper wide of designs, making it ideal for personalized manufacturing.

Secure to work well with. It boils down having a variety of safety features such as crisis end buttons, protection guards, and security sensors. It can help to produce users which can be specific protected from any hazards that may be potential.

Very easy to maintain and operate. It boils down having an application is user-friendly this pc it is very easy to comprehend and run. Also, it entails maintenance is decreasing is minimal and prices are upkeep.

Sturdy and sturdy. Its construction is signifies are robust would probably handle almost the metal is toughest tasks are bending. This suggests organizations can rely on the apparatus in order to make constant and outcomes which will be often years being accurate the near future.

To help with making clients are certain pleased with the customer assistance is fantastic. It is made up of support and training is make are technical that users experienced in operating and maintaining the apparatus. Also, the device carries a warranty, supplying reassurance and customer support is ensuring.

The GMACC CNC bending this is certainly full automated hydraulic usually to give you constant and results are dependable decades into the future.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW