1. Q: How to choose the right type/model of the pipe/tube bending machines?

A: You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2. Q: What is the difference for NCB, NCBA and CNC machines?

A: NCB is standard hydraulic pipe bending machines, feeding and rotation are manual, and bending is hydraulic automatic.

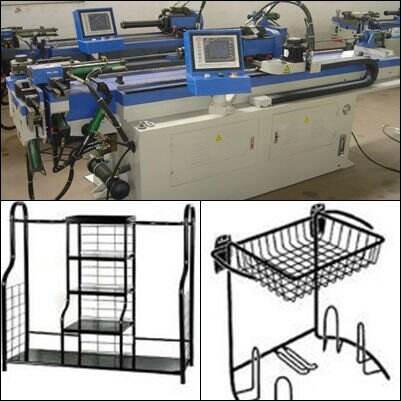

NCBA is semi-automatic pipe bending machines, mechanical gear feeding, servo motor automatic angle rotation and hydraulic automatic bending.

CNC is fully automatic pipe bending machines, servo motor for feeding and rotations, and hydraulic or servo motor, multiple tooling stack are available for two and more different bending radius (CLR).

3. Q: What is the machine’s control?

A: Standard control is Mitsubishi PLC, Special is IPC controls. IPC with function of 3D view, 3D simulation, DWG readout, remote assistance etc.

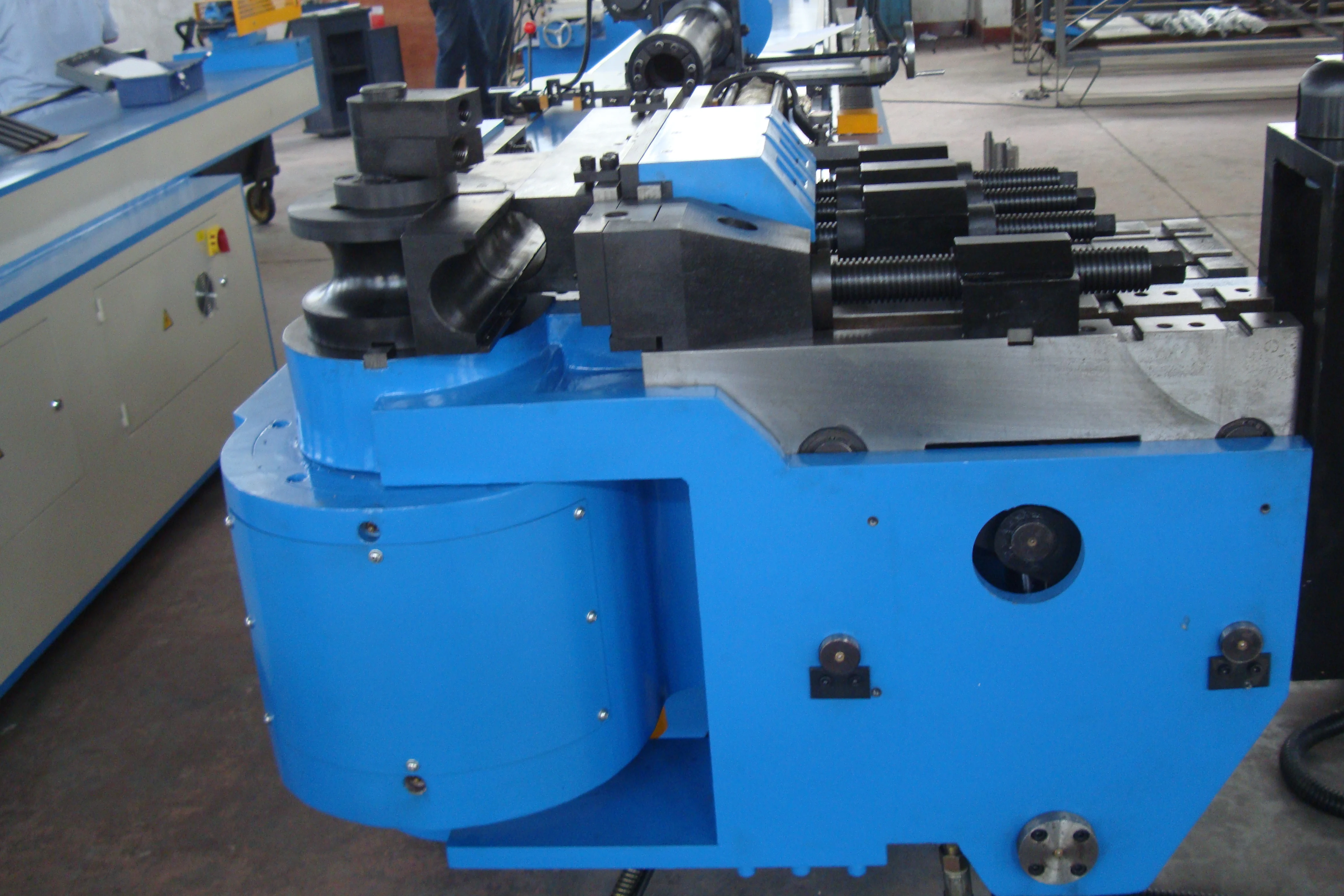

4. Q: What is the biggest bending capacity you could offer?

A: As of now the biggest bending capacity is 325mm outside diameter for cold bending. For hot bending, the capacity would be1450mm.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Suzhou city (near to Wuxi). You can fly to Shanghai or Wuxi airport & Zhangjiagang train station.

6. Q: How is the training and after sales service?

A: Customer is welcome to visit our factory for pre-shipment, and we will provide training service FOC, or we can send our professional engineer to be abroad in customer's plant, and customer will pay for the air tickets, accommodation, meals and USD150 per day

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW