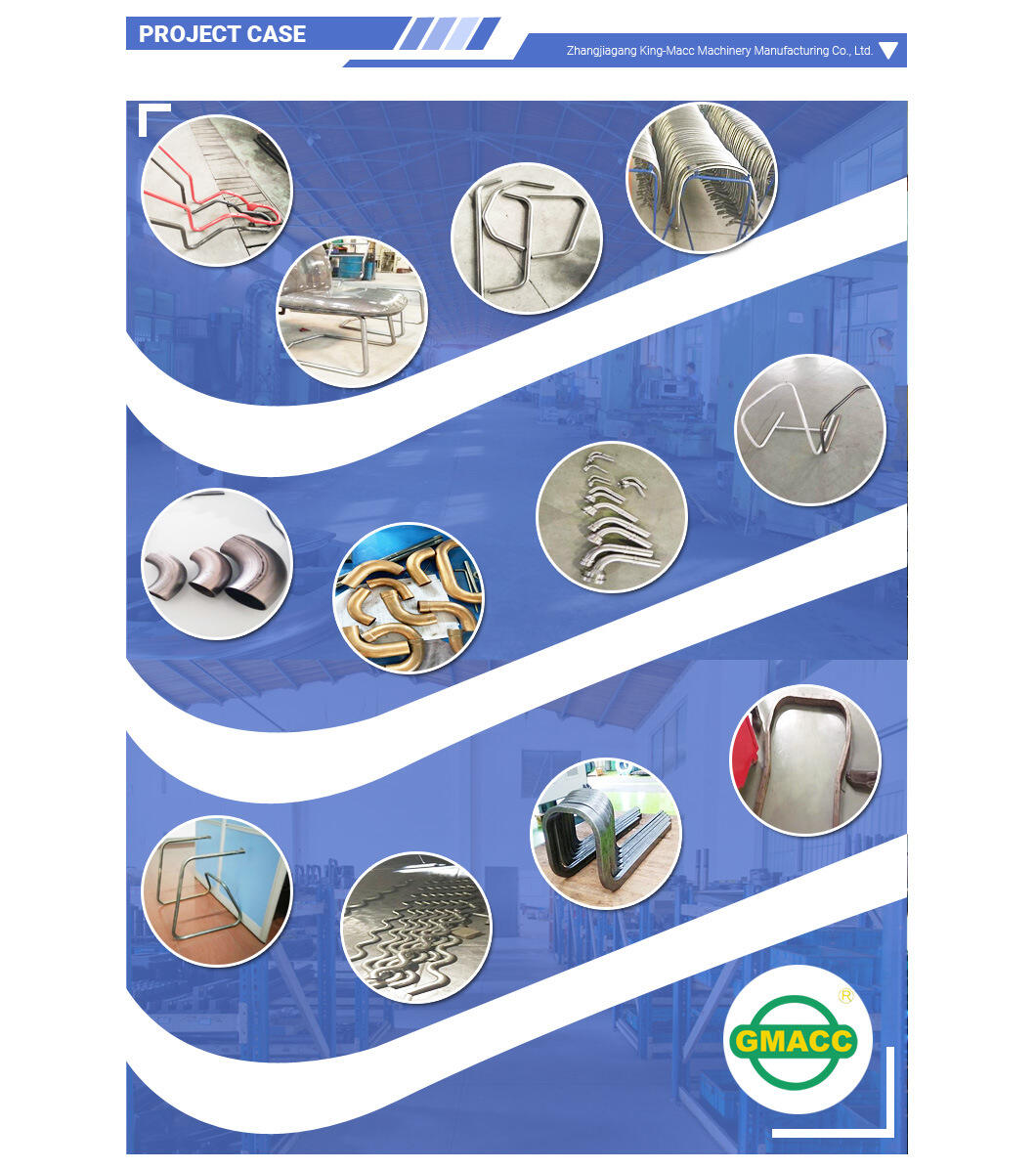

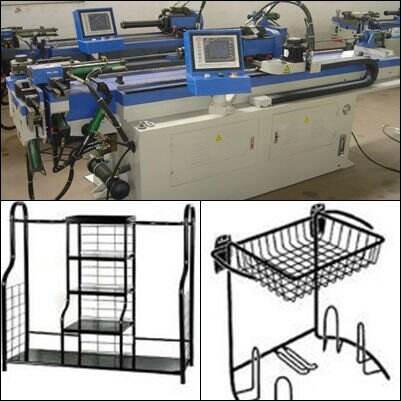

Full Automatic Pipe Bending Machine GM-SB-76CNC-2A-1S

Machine Characteristics

GM-SB-CNC Series numerical control single-head pipe bending machine is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinates of motion under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending, CNC machine also with advanced functions, such as components bending spring back compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Pipe rotating(B axis), and pipe feeding(Y axis) are both driven by servomotor. Pipe bending(C axis) is hydraulic. This machine is 2 axis with hydraulic pipe bending machine which can bend pipes very easily by PLC. If customers want to change PLC to industrial PC, it is also no problem, just add more cost

|

Name

|

Unit

|

Parameter

|

|

Max. Bending Capacity

|

mm

|

76*4

|

|

Bending Radius Range

|

mm

|

30-350

|

|

Max. Bending Angle

|

°

|

190°

|

|

Bending Speed

|

°/sec

|

30

|

|

Turning Speed

|

°/sec

|

160

|

|

Feeding Speed

|

mm/sec

|

800

|

|

Bending Precision

|

°

|

±0.10

|

|

Turning Precision

|

°

|

±0.10

|

|

Feeding Precision

|

mm

|

±0.10

|

|

Turning Servomotor Power

|

1.5kW

|

1.5

|

|

Feeding Servomotor Power

|

kW

|

1.5

|

|

Max feeding length

|

mm

|

4000

|

|

System Motor Power

|

7.5kW

|

11

|

|

Max. Pressure

|

Mpa

|

16

|

|

L*W*H (Packaging Dimension)

|

mm

|

5000*1200*1300

|

|

Weight

|

T

|

3.5

|

Machine features

1. Applicable tube material: carbons steel, mild steel, soft steel, stainless steel, aluminum, alloy, copper, brass etc.

2. Applicable tube shape: tube, solid bar, square, rectangle, oval, profile etc

3. Equipped with hydraulic-operated clamping tube, encoder-controlled bending angle with precision more or less 0.1 degree.

4. About 200 programs can be inputted into PLC, then show on dialogue-style operation touch screen, easy to learn and understand.

5. Moveable foot switch with function of auto-start, pause and emergent-shop, safe and convenient

1. Q: How to choose the right type/model of the pipe/tube bending machines? A: You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- Bending radius (CLR)

- The pipe material

- The drawings if possible

2. Q: What is the difference for NCB, NCBA and CNC machines? A: NCB is standard hydraulic pipe bending machines, feeding and rotation are manual, and bending is hydraulic automatic.

NCBA is semi-automatic pipe bending machines, mechanical gear feeding, servo motor automatic angle rotation and hydraulic automatic bending.

CNC is fully automatic pipe bending machines, servo motor for feeding and rotations, and hydraulic or servo motor, multiple tooling stack are available for two and more different bending radius (CLR).

3. Q: What is the machine’s control? A: Standard control is Mitsubishi PLC, Special is IPC controls. IPC with function of 3D view, 3D simulation, DWG readout, remote assistance etc.

4. Q: What is the biggest bending capacity you could offer? A: As of now the biggest bending capacity is 325mm outside diameter for cold bending. For hot bending, the capacity would

be1450mm.

5. Q: Where is your factory located? How can I visit there? A: Our factory is located in Suzhou city (near to Wuxi). You can fly to Shanghai or Wuxi airport & Zhangjiagang train station.

6. Q: How is the training and after sales service? A: Customer is welcome to visit our factory for pre-shipment, and we will provide training service FOC, or we can send our professional engineer to be abroad in customer's plant, and customer will pay for the air tickets, accommodation, meals

GMACC

Introducing the Automatic Steel CNC Tube Bending Machine from the perfect tool for the furniture industry. This machine is designed to simplify the bending of steel tubes and deliver precise results every time you use it. Whether you're making chairs, tables, or other furniture pieces, our tube bender is the ideal solution to ensure accuracy and save time on your production line.

A contemporary, fully-automated unit Nd difficult or soft metal pipes with ease. It features a computer numerical control (CNC) system that enables one to get a handle on the bending angle, rotation, and feeding rate regarding the tube according to your preferences. The GMACC tube bender can finish complex bending tasks in only a matter of seconds, resulting in smooth, consistent, and accurate bends each and every time using this technology.

One great thing about using this device is its effectiveness. It is simple to modify it to bend pipes multiple as soon as, enabling you to conserve some time boost your production price considerably. Can handle your preferences with simplicity whether you're coping with small or big batches., the tube bender features a touchscreen display interface that eliminates the need for manual changes, reducing the risk of human being mistake and effectiveness is improving.

Durable. A construction is sturdy from high-quality materials that can withstand the rigors of everyday use. Moreover, it needs upkeep is minimal continue it in top working condition, rendering it a cost-effective addition to your workshop.

Try the Automatic Steel CNC Tube Bending Machine from GMACC today and experience the difference it can make in your workshop.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW