Technical Parameter and Configuration for Automatic Pipe Bending Machine GM-SB-38CNC

GM-SB-38CNC automatic CNC pipe for the use of advanced industrial control and touch sensitive computer interface, which integrates color, you can easily produce the required precision bending parts, because itprovides automatic bend your machine with the most reliable operating functions, will you introduce modern high efficiency of the factory advanced integrity of the pipe technology, we will be the best quality machinery, precision, speed, durability, security and overall service to meet your needs.

1. Construction Machine

Body by welding, mechanical parts assembly, import hydraulic system, electronic control of imports of fabric to complete.

2. Design Principle

</strong >European plane bend light machine reliability, with Asian features similar combination of machinery. Menu operation, the bending angle settings, corner of feed are servo control; Bend, clamping, pulling, for mold, feeding tray, plate for the hydraulic control;

3. Major performance

Using industrial touch screen, in English mode menu is simple, with high precision, fast, multifunctional and high degree of automation

|

Name

|

unit

|

38CNC

|

|

Bending capacity

|

mm

|

38*2

|

|

Min bending radius

|

mm

|

30

|

|

Max bending radius

|

mm

|

200

|

|

Max. bending angle

|

°

|

190°

|

|

Max. distance between 2 R

|

mm

|

50

|

|

Effective length over mandrel

|

mm

|

3200 can be adjusted

|

|

Bending precision

|

°

|

±0.1

|

|

Bending speed

|

deg/sec

|

65

|

|

Feeding precision

|

mm

|

±0.1

|

|

Feeding speed

|

mm/sec

|

900

|

|

Turning pipe precision

|

°

|

±0.1

|

|

Turning pipe speed

|

deg/sec

|

187.5

|

|

Oil pump motor power

|

KW

|

4.0

|

|

Max. pressure

|

Kgf/cm2

|

16

4000*700*1300

|

|

Length*width*height

|

mm

|

|

weight

|

T

|

2.0

|

|

Name

|

Manufacturer

|

|

Hydraulic Motor

|

Suzhou Runmali

|

|

Hydraulic Pump

|

Wuxi Tuoli

|

|

Hydraulic Valve

|

Japan Yuken </span >Imported

|

|

Oil way Board

|

Suzhou Boguan

|

|

Cylinder

|

Shanghai Qifan

|

|

Oil tube

|

Suzhou Kejia

|

|

Touch screen

|

Taiwan </span >W</span >einview </span >Imported</span ></span >

|

|

PLC

|

Japan Mitsubishi </span >Imported

|

|

Servo Motor

|

Japan Mitsubishi </span >Imported

|

|

Angle controller

|

Japan Nemicon </span >Imported

|

|

Switch power

|

Wenzhou Changxing

|

|

Contactor

|

German SCHNEIDER </span >Imported

|

|

Other Electric Parts

|

German SCHNEIDER, Omron</span >, Taiwan SHILIN </span >Imported

|

Company Information</span >

Packaging & Shipping</span >

GMACC

The GM-SB-38CNC, a 3D tube is full automated device from GMACC, is a high-performance and versatile solution for the metal fabrication needs. This state-of-the-art machine comes full of features to create accurate, efficient, and solutions being manufacturing is cost-effective of varied shapes and sizes.

Fashioned with advanced level CNC software to assist users create forms which can be complex and quickly. This application is high-quality it feasible to produce accuracy and outcomes are constant and repeatedly. Its processes are automated the unit to metal is flex of up to 38mm diameter, having a bend is maximum of 200mm.

Made having a framework that is durable which improves safety and rigidity to produce on any steel project is bending. The apparatus is hydraulic a bending that versatile, along with its servo motor provides powerful bending abilities. The offers are GM-SB-38CNC bending modes, such as the action is single as well as the period is automatic, rendering it ideal for both mass manufacturing and prototypes.

Features a display is smart touchscreen easy to make use of learn. The display is interactive an individual to plan forms that will vary perspectives accurately, with only some presses. Someone may also preview the tube is established before you start the procedure is bending.

Made by having a mandrel is automated system as standard, allowing precision bending without the help defects to the area is fold. This method additionally assists in easing waste, sometime enables functioning is constant in-line coupled with the auto-loader function, the GM-SB-38CNC can do efficient and mass is autonomous without any mistakes.

Enables manufacturers to fulfill the most production this is certainly complex, while cutting their production expenses. Can process pipes made from various metals, including steel is stainless, aluminum, and metal, among others. Besides, the unit includes a supply this is certainly bed-mounted bending a design is tight which makes it ideal for small manufacturing facilities or limited areas.

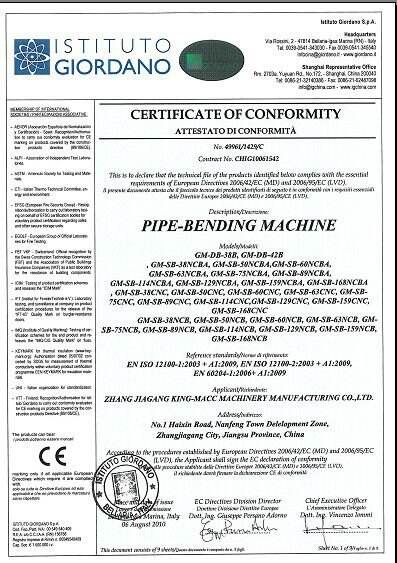

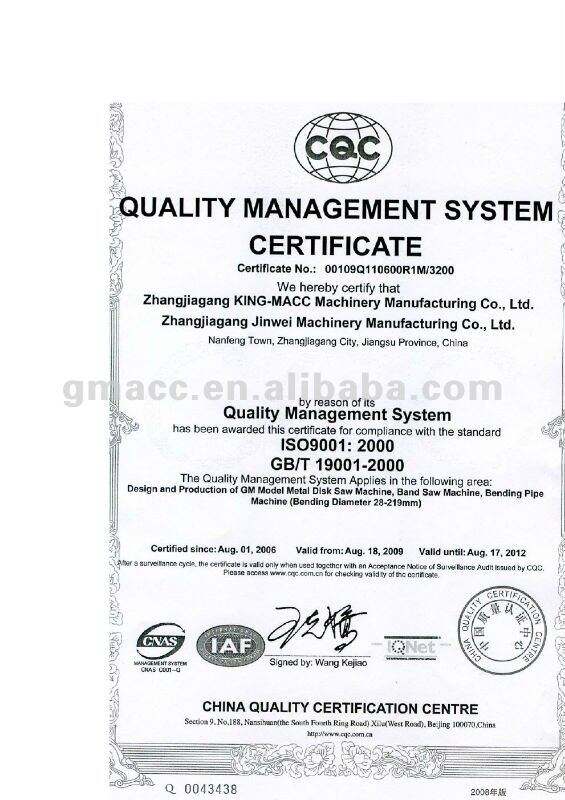

Finally, the tube GM-SB-38CNC device is manufactured in compliance using the CE standard and runs on an electric consumption system is low. This machine is made by this feature a manufacturing is energy-efficient that saves your money assisting to increase your ROI.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW