Plumbing and metalworking are key jobs that maintain our homes safe and perform well. Plumbers fix pipes and ensure water gets to where it needs to go, metal workers make metal parts for many purposes. Plumbers and metal workers both have jobs they need to work on, which is why there are tools that make the job easier for them, including a hydraulic pipe bender. So here, we will discuss the hydraulic pipe bender.

Many of these pipes were bent by hand, as plumbers and relevant metal workers often do their work to fit into very specific spaces. Other times they have to fashion curved or bent pipes and angles. This is where a hydraulic pipe bender shines. Helps them in very efficiently bending pipes without them having to put much effort. This hydraulic pipe bender from GMACC is an example of such a tool. This has an intuitive and easy to use design, thus, making stainless steel tube bending suitable for both newbies and seasoned workers. This is, and it makes exact bends which are vital during their projects.

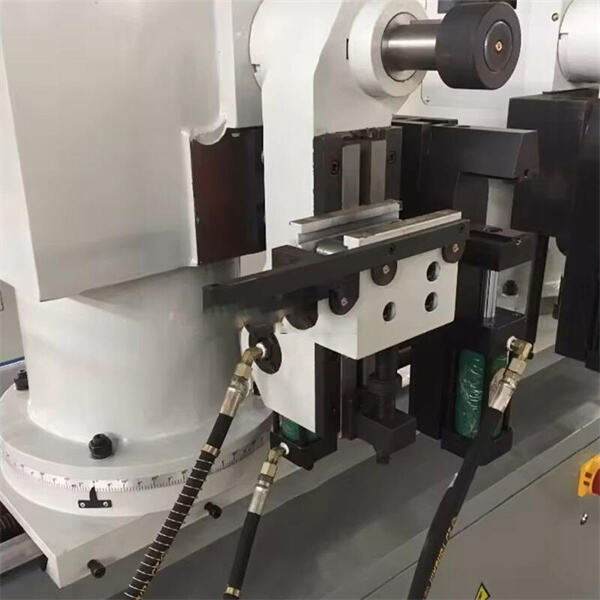

Hydraulic Pipe Bender: A hydraulic pipe bender bends pipe by using hydraulic pressure. So let us take it one step at a time. Bending the Pipe Into Position. The worker starts with inserting the pipe in the bender. After that, they decide the degree at which they will bend the pipe. Then they lower a hydraulic pump and press the pipe. This causes the pipe to give in and bend at whatever angle he chose. After one side is bent, the pressure will be relieved and then take out the bended pipe. A single-plane design, this method of GMACC bending pipes is less intimidating than hand-bending and guarantees a consistent degree bend.

They help in bending the pipes into various shapes and sizes. The best thing about hydraulic pipe benders is that they can bend the pipes of any diameter from small to big it could make sharp angles, smooth curves, and even spirals in these pipes. Plumbers and metal workers find this feature particularly helpful because it enables them to install pipes in tight or small areas. The GMACC1500 exhaust bender is a powerful bending tool even before you consider the extra set of customizable bending parts that come with it (bending dies). The bender is especially versatile as a result these parts enable users to create bends of dozens of different varieties.

There are a few important things to consider when deciding on which hydraulic pipe bender is perfect for your requirements. The initial step is understanding the sizes of the tubes that you will be bending. Ensure the bender you select is rated for those sizes and powerful enough to do the job. Then think about the bends you need to make. It is crucial to have the bender allied to those correct angles. And finally, the bender's price and durability. This hydraulic pipe bender is a no-nonsense option that's priced affordably—well, reasonably so considering its price point and reliable enough to last for future projects.

A nice thing about a hydraulic pipe bender is that it can be quite safe to use, provided you keep in mind a few safety tips. Attaching the bender to a workbench. It will also secure the bender from tipping over or scooting around, which is a safety hazard when it comes time to use it. You should be wearing protective gloves and goggles after that. The type of hand and eye protection you don will keep you safe from cuts and flying damage to your eyes as a result of the rotating pipe. Finally, follow the recommendations and instructions provided by the bender manufacturer. The Full-Auto Hydraulic CNC Tube Bending Machine is supplied with clear instructions that are required for a safe and successful use of the die.

With Hydraulic pipe bender technological advancement pipe benders have introduced modern CNC technology as well as high-speed milling technology and intelligent control systems making the machine more precise and stable during the production process These advancements in technology do not just increase the efficiency of production but also ensure the quality and precision of the pipe bending and fulfill the demands for processing of different workpieces

Pipe benders manufacturers provide Hydraulic pipe bender to meet your specific demands. They are able to design and manufacture in accordance with the requirements of the client, ensuring that the angle, accuracy and shape of bent pipes meet the specifications of their product. This service isn't only tailored to the individual needs of the client however, it also improves the quality of the product and its efficiency.To sum up, the producers of pipe bending machines offer users efficient and accurate solutions for pipe bending through the use of their technological advancements, efficiency in production, the assurance of safety, energy savings and environmental protection, as well as personalized service. They also cater to the demands of various fields and industries.

By optimizing the production process and adopting a modular design pipe bending machine manufacturers can easily adjust the machine according to production demands, Hydraulic pipe bender improving production efficiency. While at the same time the control system's intelligent technology controls the manufacturing process continuously to ensure that the equipment is in top condition and thereby increasing the efficiency of production.

Pipe benders take care to ensure the safety of their operators when designing the machine and adopt multiple safety protection measures like Hydraulic pipe bender emergency stop buttons or infrared devices for protection to ensure the safety of employees throughout the manufacturing process The machine is also capable of adapting to harsh environments and will work efficiently in harsh environments It provides the user with a confidence in the production