Lasers are powerful tools and this is why lasers can dissect through many substances close to the line on the x axis. We create parts for industries from a large variety of laser cut tubing using only the best tubular steel at GMACC. In layman's terms, we can now fabricate parts which should make things work better and more safely.

Laser cutting is a process that involves the use of light beams to cut materials. Because it is so accurate, we can create complex shapes and designs in tubing, identical to GMACC's product electric conduit bender. Laser-cut tubes are also widely used in our parts production lines for industries such as auto, aviation, and even medical devices. By this technology, we can take a guarantee that each part is manufacturing how it should be and which is crucial for the proper operation and safety of products using them.

The accuracy of laser cut tubing is one of the greatest advantage. Laser cutting is extremely precise, as a result of which we can make high quality designs and unique shapes that are otherwise difficult to do without using laser. This matters a great deal in numerous industries, wherein parts necessitate functioning just so and playing nicely. Missing the mark for this hand-off is visible in a typical car manufacturing process, if a part not well sequence and can bring many consequences. This is why we work hard on every part being perfect.

One of the best things about laser cut tubing is how fast it works, similar to the stainless steel tube bending from GMACC. Parts can be cut quickly, and laser cutting the make parts can be done more efficiently. This is important for a plant or a company where high possibilities of quick execution are required. Time is Money — In the modern era we are living in, being able to crank out parts quickly can save businesses and help them stay toe-to-toe with customer demands.

Laser Cut Tubing is Changing the Way We Make Things (and its pretty Awesome) Laser cutting is the best way to produce parts in many industries, which is due to its ability for accuracy and speed, identical to GMACC's product bender pipe hydraulic. In each of these cases, we believe this are just the tip of the iceberg and more applications for laser cut tubing will arise as technology continues to advance. The cognitive science is emerging for manufacturing process and innovations.

Numerous industries requiring components that come in complex shapes and designs, along with the electric conduit benders innovated by GMACC. These are perfect parts for lasers as they can cut through many materials with incredible precision. This is how we can design even intricate parts that will fit perfectly and work as intended. This part of the process is crucial in areas such as aerospace where parts must be both strong and light, something that laser cutting allows us to provide.

One of the best ways to work is using a laser cut tubing, as well as the GMACC's pipe bending. This will ultimately help making the process faster, hence reducing waste. These parts can be manufactured quickly and with high precision by the use of lasers, which results in a short production time. That means more parts produced less time - An efficient production process that companies that wish to boost their volume and profit margins can enjoy.

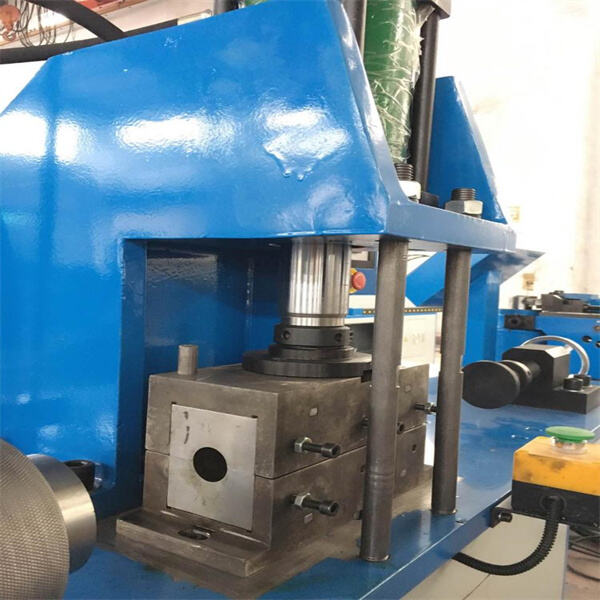

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Laser cut tubing and environmental protection, as well as tailored services to meet the requirements of various fields and industries.

By optimizing the Laser cut tubing and adopting a modular design pipe bending machine makers can adapt the equipment to production needs, drastically increasing the efficiency of production. In addition the control system's intelligent technology monitors the process of production continuously to ensure that the equipment is always in good working order and thereby increasing the efficiency of production.

Pipe bending machine manufacturers take Laser cut tubing to ensure the safety of their workers throughout the design process and implement a variety of safety measures such as emergency stop buttons, safety gratings or infrared safety devices to ensure that workers are safe while they are working. Additionally, the machine is also highly adaptable to environmental conditions and is able to operate safely in difficult environments, providing the users with confidence in their production.

With Laser cut tubing technological advancement pipe benders have introduced modern CNC technology as well as high-speed milling technology and intelligent control systems making the machine more precise and stable during the production process These advancements in technology do not just increase the efficiency of production but also ensure the quality and precision of the pipe bending and fulfill the demands for processing of different workpieces