GMACC telah merevolusi cara industri memotong pipa menggunakan alat laser yang sangat kuat ini yang benar-benar baru. Laser yang digunakan untuk pemotongan pipa sangat kuat dan dapat memotong dengan cepat serta presisi tinggi. Inovasi teknologi baru ini adalah perubahan drastis dari metode lama memotong pipa karena jauh lebih efisien dalam hal waktu, dan menghasilkan pekerjaan yang lebih baik. Karena pemotongan laser pipa ukurannya kecil, itu juga memakan ruang lebih sedikit di pabrik.

Berkat teknologi laser, pembuatan lubang pada tabung telah menjadi jauh lebih nyaman bagi industri untuk memotong berbagai pipa. Laser pemotong osilasi ini membuat proses tersebut lebih sederhana dan aman, menghemat banyak waktu maupun uang bagi perusahaan. Ingatlah bahwa metode lama pengangkutan pipa sangat lambat dan membutuhkan terlalu banyak energi, yang sering kali menghasilkan potongan yang tidak rapi. Hal ini sering membuat pekerja perlu melakukan pekerjaan tambahan untuk memperbaiki kesalahan tersebut. Dengan teknologi GMACC baru ini, industri sekarang dapat langsung menghasilkan potongan berkualitas tinggi yang memerlukan sedikit atau tidak sama sekali perbaikan dan penyempurnaan.

GMACC telah merancang sistem laser untuk pemotongan pipa yang cukup akurat dan bekerja sangat baik. Alat laser ini membantu memotong pipa tanpa mendorong atau melukainya. Ini bagus karena menghasilkan potongan yang lebih berkualitas tinggi dan membutuhkan pengolahan pasca lebih sedikit, pada akhirnya menghemat waktu dan uang perusahaan. Jadi, industri dapat memotong pipanya dengan cepat dan dalam waktu singkat dengan menggunakan sistem laser ini, membuat mereka lebih efisien. Selain itu, ini tabung potongan laser peningkatan produktivitas adalah kunci untuk tidak hanya mengejar kecepatan pasar, yang bergerak cepat saat ini.

Teknologi pemotongan pipa laser yang diperkenalkan oleh GMACC tidak kurang dari sebuah keajaiban di sektor manufaktur ini. Pabrik-pabrik menggunakan laser untuk memenuhi lebih banyak pesanan dalam waktu lebih singkat dan dengan demikian mendapatkan persentase keuntungan yang lebih besar. Teknologi laser memastikan bahwa proses pemotongan dipercepat secara signifikan dan, selain itu, jauh lebih aman daripada menggunakan metode lama pemotongan serta menghasilkan limbah yang jauh lebih sedikit. The pemenggal pipa hidraulik laser untuk memotong pipa, kemudian memungkinkan produksi yang bahkan kurang kompleks dan oleh karena itu membantu meningkatkan keuntungan di antara perusahaan tetapi juga memastikan kepuasan pelanggan berkat penanganan yang tepat.

Teknologi pemotongan pipa laser adalah pilihan yang tepat ketika Anda membutuhkan potongan pipa yang kokoh dan presisi. Laser mampu memastikan bahwa setiap potongan presisi dan sama dengan yang lainnya, sehingga pipa-pipa tersebut memiliki ukuran yang seragam saat keluar dari jalur produksi. Ini sangat krusial di industri-industri di mana menjaga kualitas tinggi penting agar produk dapat bekerja sesuai yang diharapkan. Sistem laser memungkinkan pengurangan kesalahan yang disebabkan oleh faktor manusia dalam metode pemotongan tradisional. Ini pelengkungan pipa hidraulik membantu meningkatkan proses pemotongan secara keseluruhan dan membuatnya lebih kuat, pada akhirnya membantu perusahaan menghabiskan waktu mereka untuk hal-hal yang penting.

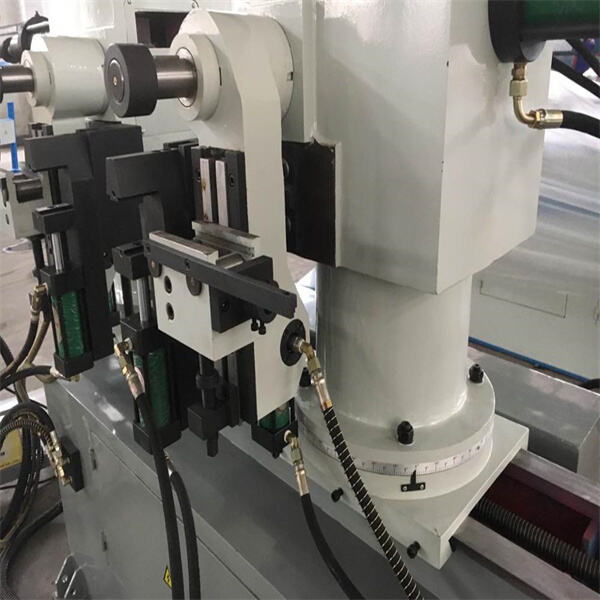

Laser pemotongan pipa pada mesin penyiku pipa menawarkan layanan khusus untuk memenuhi permintaan khusus. Mereka dapat merancang dan membangun sesuai dengan spesifikasi klien untuk memastikan bahwa sudut, presisi, dan bentuk pipa penyiku sepenuhnya memenuhi spesifikasi produk mereka. Layanan ini tidak hanya dirancang khusus untuk memenuhi persyaratan klien tetapi juga meningkatkan kualitas dan efisiensi produk. Secara keseluruhan, produsen mesin penyiku pipa memberikan solusi penyiku pipa yang andal, aman, akurat, dan presisi kepada pelanggan mereka berkat inovasi teknologi, produksi efisien, serta keamanan, hemat energi, ramah lingkungan, dan layanan personalisasi, memenuhi kebutuhan berbagai industri dan bidang.

Pabrikan mesin penyiku pipa fokus pada keselamatan dan pemotongan laser pipa pekerja saat fase desain. Mereka menerapkan berbagai tindakan keamanan, termasuk grating keamanan, tombol darurat, serta perangkat keamanan inframerah untuk menjamin keselamatannya selama produksi. Selain itu, peralatan ini juga sangat fleksibel terhadap kondisi lingkungan dan dapat beroperasi dengan aman dalam berbagai kondisi, memberikan pelanggan keyakinan dalam produksi mereka.

Mesin penyiku pipa menjadi lebih presisi dan stabil dalam produksi berkat perkembangan teknologi CNC dan sistem kontrol canggih. Perkembangan teknologi ini meningkatkan efisiensi produksi serta ketepatan dan kualitas penyiku pipa. Mereka juga mampu memenuhi kebutuhan pengolahan berbagai workpiece yang rumit.

Mesin pemotong pipa laser dapat disesuaikan dengan kebutuhan produksi melalui penerapan desain moduler dan optimasi proses manufaktur. Hal ini dapat secara signifikan meningkatkan efisiensi produksi. Sistem kontrolnya cerdas dan memantau produksi secara real waktu untuk memastikan peralatan berada dalam kondisi terbaik. Ini meningkatkan efisiensi produksi.