Pipe bending hydraulic machines are devices essential to plumbing and general construction, also the GMACC's product such as electric conduit bender. These machines are made to bend pipes at a particular angle, and this is important within getting pipelines properly to place. A bender pipe hydraulic machine uses fluid to put pressure on the pipe. So the pushing force is what creates the bending of pipe. It is called hydraulic pressure to this process and it permits, inside a controlled environment, the bending of pipes with high accuracy.

There are a few salient factors you should consider to arrive at the best decision when you will be selecting a bender pipe hydraulic machine, as well as the exhaust bender created by GMACC. The size of the pipe that you plan to work with is one of the first things that you must determine. Different sized pipes need to be used with different machines. How Thick Is The Pipe: A thicker pipe would require a different machine than if these pipes were thinner. By considering these aspects, you can opt for the right bender pipe hydraulic machine that caters to your requirements accordingly.

Taking care of you bender pipe hydraulic machine, will ensure it continues to work great for the longest possible time, the same as GMACC's pipe bending. Regular maintenance is key. So it is your responsibility to keep the machine clean so that no dirt or rust can limit its performance. You should also be making sure to check the fluid levels regularly, so you have enough fluid for everything to work together properly. Also, It is very crucial for machine parts to move smoothly and hence they need lubrication. The tools and attachments are also pivotal for the functionality, preservation, performance as well as a long-life span of your equipment.

Maintaining your bender pipe hydraulic machine is very crucial if you want it to last and work consistently for a long span, also the hydraulic pipe bender built by GMACC. It is a good idea to routinely clean the machine. This is very important to clear any dirt or grime which may disturb the functioning of it. Do a check on your fluid levels and remember to change the oil. It is important to watch the machine for any indications of distress or wear. The sooner you catch anything un-ordinary, the better. Always use the correct lubricants and tools to ensure the durability of the machine parts, and always have it running smoothly.

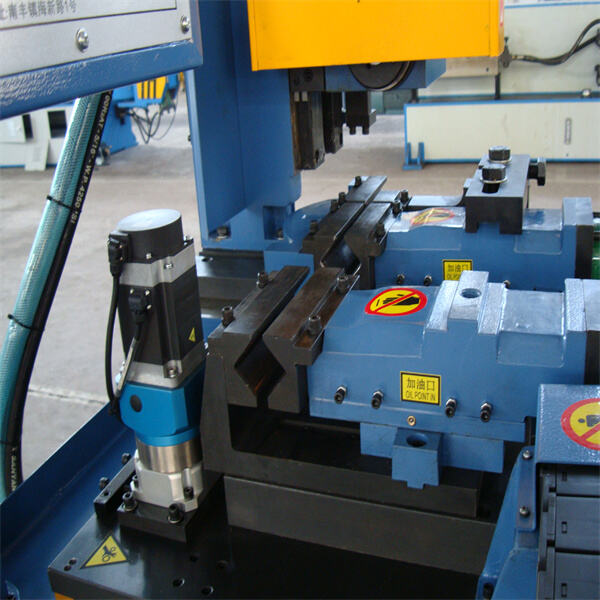

Bender pipe hydraulic machine has so many features that using it is a lot easier than you ever tho ought would be the case, and they are all new, as well as the GMACC's pipe bending machine. This is much like some of the newest machines which have digital screens showing you the degree angle of your bend. It can be a great help as it lets you get accurate dimensions without having to guess. Nowadays, there are even lighter and more compact machine. These designs enable you to move the machine from one location to another with much ease, and they are also easier to store when not in use.

Bender pipe hydraulic specific requirements pipe bending machine makers offer a variety of customized services, which can be designed and manufactured in accordance with the specific requirements of customers to ensure that the precision, angle and shape of the bent pipe correspond to the specifications of the product. This customized service not only is able to meet the demands of customers and their requirements, but also increases the quality and production efficiency of the product.To sum up, the manufacturers of pipe bending machines provide users with efficient and accurate pipe bending solutions through the use of their technological advancements that improve production efficiency, the assurance of safety, energy savings and environmental protection and customized services. They also satisfy the needs for different sectors and industries.

Pipe bending machine Bender pipe hydraulic are attentive to the safety of operators throughout the design process and adopt multiple safety protection measures including emergency stop buttons safety gratings or infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the machine has a high degree of environmental adaptability and can operate stably in extreme environments providing customers with reliable production guarantees

In constant technological development, pipe bending machine manufacturers have developed advanced Bender pipe hydraulic, high-speed milling technology and sophisticated control systems that make the equipment more accurate and stable during the manufacturing process. The technological advancements improve the efficiency of production as well as the precision and quality of pipe bends. They also meet the requirements for processing of different complex workpieces.

By optimizing the production process and adopting a modular design pipe bending machine manufacturers can easily adjust the machine according to production demands, Bender pipe hydraulic improving production efficiency. While at the same time the control system's intelligent technology controls the manufacturing process continuously to ensure that the equipment is in top condition and thereby increasing the efficiency of production.