This is more of an adult custom car or motorcycle enthusiast tool, and to kids it may seem a bit boring but this can still be great fun for both the helpers and kids. This is something really cool to know if you like building or fixing (bikes/toys). And it may lead to a brand new world of creativity and DIY antics!

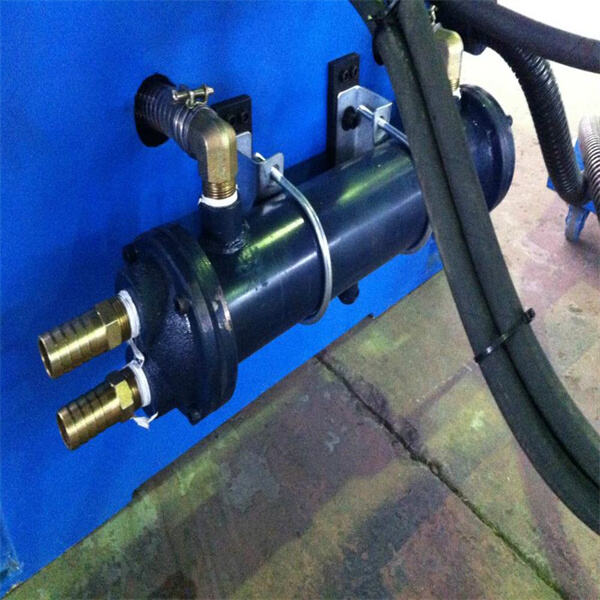

Now as for the piece of equipment a steel tubing bender is; it is a tool which bends metal tubes or pipes into all sorts of shapes. This works the same way as when we press out a tube at one end and hold it suspended from another. With patience, you can bend the tube to whatever angle length for your needs.

The first step in creating accurate angles with a steel tubing bender is to measure the tube that you are bending to determine how long you would like it to be. Then follow that by outlining a line of where you want the bend to start and also finish. It is highly useful to identify exactly where you will later have to bend the tube. Next, simply adjust the bender to the correct angle and tighten it so that the tube will not move when you are working.

For instance, if you like developing things like chairs or tables, after that making use of a tubes bender to create durable as well as custom frames should be an excellent suggestion. With this tool, you can also easily bend metal parts that should not be bent in the flat... and make your projects even better.

A steel tubing bender will help you repair or replace parts on the cars or machinery that you service in your line of work. For example, you can create exhaust pipes that fit just right or some strong supports to hold things in place really well. Not only is this a good thing, but it feels really rewarding when you finish the project.

At a jobsite, wherever things are made--that is especially true for a steel tubing bender. Whether you are manufacturing car parts or construction supplies, this tool will help you to produce a typical bend in metal tubes without any variations. This equates to consistency in projects which is pretty invaluable.

The first and the foremost advantage is that you do not loose the material by cutting angles before hand, instead steel tubing bender will help you achieve what ever angle you require. It is time-saving and also contributes towards the environmental cause by lowering the amount of material goes to waste.

Pipe benders take care to ensure the safety of their operators when designing the machine and adopt multiple safety protection measures like Steel tubing bender emergency stop buttons or infrared devices for protection to ensure the safety of employees throughout the manufacturing process The machine is also capable of adapting to harsh environments and will work efficiently in harsh environments It provides the user with a confidence in the production

Steel tubing bender machines can be adjusted to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real time to ensure that the equipment is in top condition. This boosts the efficiency of production.

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Steel tubing bender and environmental protection, as well as tailored services to meet the requirements of various fields and industries.

Through continuous technological innovation, Steel tubing bender have developed advanced CNC technology with high-speed milling technologies and intelligent control systems, making the machine more precise and stable throughout the production process. These advancements in technology do not just increase the efficiency of production but also guarantee the quality and precision of the pipe bending and meet the processing needs of various complex workpieces.