GMACC

Sino-italijanski CNC savijač cijevi/tube bender GM-SB-50CNC-2A-1S je stvarno učinkovit i inovativni rješenje za savijanje cijevi i trubova s preciznošću. Ovaj revolucionarni proizvod je stavka koja se tiče suradnje između kineskog i italijanskog opreme, kombinirajući svoje vještine kako bi pružili vrhunski proizvod. Model GM-SB-50CNC-2A-1S postaje najnovije dodavanje u seriju GMACC CNC savijača cijevi/tube benders, a impresivne značajke koje ima čine ga izrazito privlačnim na tržištu.

Model GM-SB-50CNC-2A-1S je dizajniran za maksimalnu fleksibilnost i moći će upravljati nizom različitih veličina cijevi i cevi. Može savijati cijevi ili cevi s promjerenjem do 50mm, a dolazi s nizom alatnih opcija koje omogućuju različito savijanje. Sino-italijanski CNC savijač cijevi/tube savijač GMACC GM-SB-50CNC-2A-1S može završiti posao s preciznošću i učinkovitostjo, bez obzira na to je li također važno savijati cijevi za hidrauličke sustave, isparnice ili druge primjene.

Jedna od najboljih značajki modela GM-SB-50CNC-2A-1S je njegov napredni CNC sustav. Taj sustav olakšava postavljanje i izvršavanje složenih nizova savijanja, osiguravajući stalnu preciznu ponovljivost. Sučelje za upravljanje je intuitivno i korisniku prijateljsko; pomoću dodirnog zaslona softver omogućuje operatoru jednostavno unijeti većinu funkcija i postavki koje su potrebne.

Sino-italijanski CNC savijač cijevi/tubova GM-SB-50CNC-2A-1S može se izraditi za trajnost i dugotrajnost. Njegova čvrsta okvira i učinkoviti hidraulički sustav mogu izdržati čak i najzahtjevnije zadatake savijanja, a uređaj je izrađen tako da zahtijeva minimalnu održavanja tijekom svojeg života. To osigurava da je to ekonomično rješenje za tvrtke koje žele optimizirati svoje postupke savijanja i smanjiti neaktivne vremena.

Sino-italijanski CNC savijač cijevi/tubova GM-SB-50CNC-2A-1S je lijepo napravljen uz obzir na sigurnost uz impresivnu performansu. Dostupan je s nizu značajki za sigurnost, uključujući situacijski hitni gumb, zaštiteni pregrade i automatski isključivanje. Ove značajke pomažu da štite operatere od nesreća dok osiguravaju da oprema radi na optimalnim razinama sigurnosti.

CNC stroj za savijanje cijevi

Karakteristike Stroja

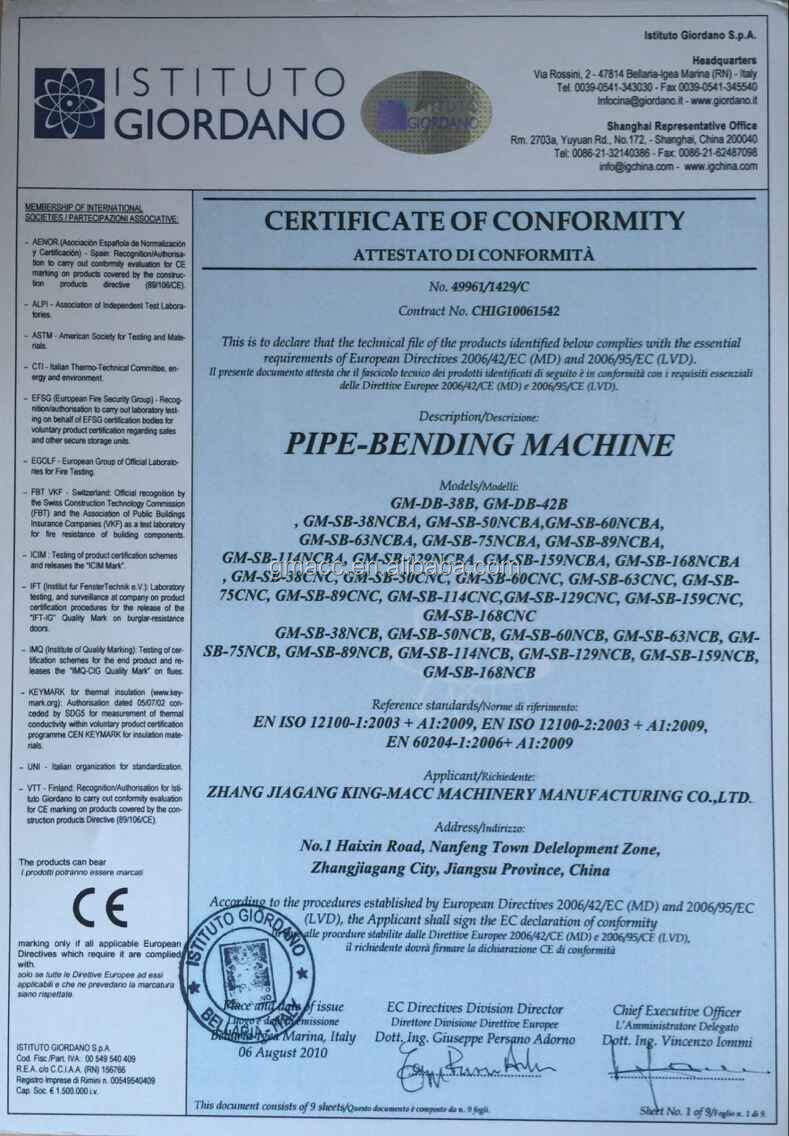

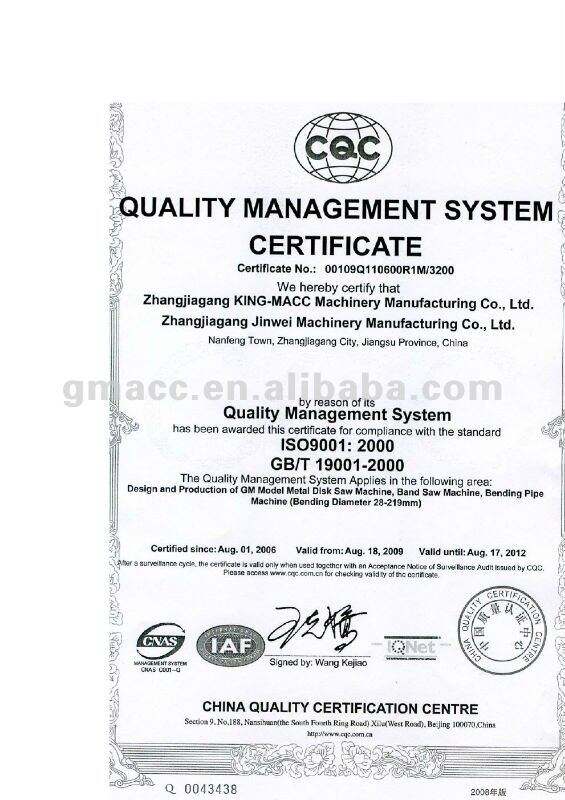

Ova serija je posebno prilagođena zahtjevima profesionalnog svjetskog tržišta. Sve dijelove, strukture i karakteristike slične su standardu mašinske inženjerije iz Europe. Naše profesionalno iskustvo i crtežni planovi za Električno, Elektronsko, Hidraulično i mašinsko od poznatih tvrtki donose unapređenje sustava strojeva na točan i privlačan performans.

Serija GM-SB-CNC brojevne kontrole jednozaglavljenih strojeva za savijanje cijevi je proizvod kombinacije naše tehnologije i napredne talijanske tehnologije, integrirane s strojevima, hidrauličkim sustavima i električnim sustavima. Ova serija koristi VDU dodirni zaslon za upravljanje, na koji se mogu unijeti, pohraniti i prikazati različiti podaci o savijanju i naredbe. Tri koordinate kretanja Y, B, C precizno se kontroliraju industrijskim računalom što omogućuje punoautomatsko savijanje s ili bez mandrela. CNC stroj također ima napredne funkcije poput kompenzacije za povratnu elastičnu deformaciju komponenti, samodiagnosticiranja pogrešaka i upozorenja, čuvanja memorije nakon isključivanja, automatskog maširanja i sigurnosne zaštite. Savijanje cijevi (os C), rotacija cijevi (os B) i podnošenje cijevi (os Y) su sve pogone zatvorenim servoposkačem. Napredna tehnologija, visoka automatizacija i pouzdanost, te integrirani dizajn čine stroj za savijanje cijevi sa brojevnom kontrolom jednom od najboljih strojeva za obradu cijevi u svijetu.

Glavni tehnički parametar

|

Naziv

|

Jedinica

|

Uređaj za upravljanje

|

|

Maksimalna sposobnost savijanja

|

mm

|

50*2

|

|

Opseg radijusa savijanja

|

mm

|

20-250

|

|

Max. kut savijanja

|

°

|

190°

|

|

brzina savijanja

|

°/sek

|

2300

|

|

Brzina okretanja

|

°/sek

|

45

|

|

Brzina opreme

|

mm/sec

|

200

|

|

Preciznost savijanja

|

°

|

±0.10

|

|

Preciznost okretanja

|

°

|

±0.10

|

|

Preciznost davanja

|

°

|

±0.10

|

|

Snaga servomotora za okretanje

|

KW

|

1

|

|

Snaga servomotora za uticaj

|

KW

|

0.75

|

|

Učinkovita udaljenost krozlaska

|

mm

|

2300

|

|

Snaga motora sustava

|

KW

|

5.5

|

|

Maks. tlak

|

MPa

|

16

|

|

Obujam dostave ulja pompe

|

L

|

17

|

|

D*Š*V (Dimenzije pakiranja)

|

mm

|

4000*800*1300

|

|

Sredstva

|

T

|

2.5

|

Značajke:

1. Primjenjiv materijal cijevi: ugljična olovo, obična olovo, meka olovo, nerđajuća olovo, aluminij, spoj, bakar, bronz itd.

2. Primjenjiv oblik cijevi: cijev, čvrsti šip, kvadratni, pravokutni, ovalni, profil itd.

3. Upravljano preko PLC-a i posjeduje ručne, poluautomatske i potpuno automatske funkcije.

4. Y, B, C tri koordinate kretanja pod preciznom kontrolom industrijskog računala što omogućuje potpuno automatsko savijanje s mandrelom ili bez mandrela.

5. Opremljen hidrauličkim čepljenjem cijevi, kodirnikom kontrolira kut savijanja s preciznošću više ili manje od 0,1 stupnja.

6. U PLC se može unijeti oko 200 programa, a zatim se prikazuju na dijaloškom tipu dodirnom ekranu, lako je naučiti i razumjeti.

7. Dostupni su različiti jezici dodirnog zaslona po zahtjevu.

8. Primjena hidrauličke klape i ulja put tablice omogućuje jedstvenu kontrolu radnji kako bi se produžio životni vijek hidrauličkih dijelova.

9. Vodički modul ima pomoćnu funkciju tlačenja te istovremeno poseduje funkcije ponavljanja i ponovnog ulaska, što može skratiti duljinu vodičkog modula.

10. Funkcija brojača može točno prebrojati količinu radnih dijelova i spremiti podatke bilo uključenom ili isključenom stanju.

11. Automatski sistem mastila zaštiti komponente i povećava radno životinju stroja.

12. Posjeduje funkciju automatskog otkrivanja pogrešaka i funkciju ograničavanja zaštite, što olakšava brzo i jednostavno uklanjanje ili mijenjanje pogrešaka.

13. Pomjerljivi nogasti prekidnik s funkcijom automatskog pokretanja, pauze i hitne zaustavke, siguran i praktičan.

14. Opcionalna funkcija sporo okretanja jezgra.

15. Opcionalna funkcija spore kretanje.

16. Opcionalna funkcija očekivanja izvlačenja mandrela.

Naše usluge

1) Promatranje i testiranje

Nakon što primimo 30% unaprijed plaćene depozita, počinjemo s proizvodnjom. Kada je stroj završen, kupci dolaze da posjetuju i samostalno ispitaju stroj, dok im stroj ne zadovolji, onda mogu platiti preostalu sumu od 70%.

2) Tehnički dokumenti

Prodavač treba kupcu dostaviti dokumentaciju za montažu i uskladištenje unutar 5 dana nakon što je ugovor dostupan, a ostale povezane dokumente dostaviti prije otpreme.

3) Poslužiteljska usluga nakon prodaje

Poslužljivost nakon prodaje obavlja se od strane prodavača. Prodavač će besplatno pružiti kupcu sve vrste tehničke podrške putem telefona, faksa ili e-pošte. Nakon jednogodišnjeg perioda garancije, osiguravamo vam životnu održavanje.

4) Montaža

Pružamo električne upravljačke sheme i instrukcijsku knjigu za montažu s engleskim uputama. Ako je potrebno, možemo poslati 1 ili 2 inženjera u zemlju kupca za montažu i obuku.

Često se javljaju pitanja

1. P: Kako odabrati strojeve za savijanje cijevi/tubova?

A: Morate nam obavijestiti sljedeće detalje:

- Najveći vanjski promjer:

- Opseg debljine zida:

- Radijus savijanja (CLR):

- Materijal cijevi:

- Crtževe, ako je moguće:

2. Q: Koji je razlikovanja između strojeva NCB, NCBA i CNC?

A: NCB su standardne mašine za hladno savijanje cijevi, snabdjevanje i rotacija su ručne, dok je savijanje hidraulički automatsko

NCBA su poluautomatske mašine za savijanje cijevi s mehaničkim optuživanjem preko zupčanika, automatskom kutnom rotacijom pomoću servomotora i hidrauličkim automatskim savijanjem.

CNC su potpuno automatske mašine za savijanje cijevi, servomotor za snabdjevanje i rotacije, a hidraulika ili servomotor za savijanje, raspoloživi su višestruki alati za dva i više različita radijusa savijanja (CLR).

4. Q: Što je kontrola mašine?

A: Standardna kontrola je Mitsubishi PLC, posebna je IPC kontrola. IPC ima funkciju 3D prikaza, 3D simulacije, DWG čitanja, udaljenog pomoćnika itd.

5. Q: Koji je najveći kapacitet savijanja koji možete ponuditi?

A: Do sada je najveći kapacitet savijanja 325mm vanjskog promjera za hladno savijanje. Za toplinsko savijanje, kapacitet bi bio 1450mm.

6. Q: Gdje se nalazi vaša tvornica? Kako mogu posjetiti tu tvornicu?

A: Naša tvornica se nalazi u gradu Suzhou (blizu Wuxia). Možete letjeti na aerodrom ili željezničku stanicu u Shanghaiu ili Wuxiju.

7. Q: Kako je obuka i poslijeprodajni servis?

A: Kupac je dobrodošao da posjeti našu tvornicu prije slanja robe, a mi ćemo pružiti besplatan obuku, ili možemo poslati našeg stručnog inženjera u inostranstvo u proizvodnju kupca, a kupac će platiti avionske karte, smještaj, hrana i USD100 po danu.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW