GM-SB-63NCBA أوتوماتيكية ثلاثية الأبعاد

آلة ثني الأنابيب

الميزات:

1. المواد الأنبوبيّة المستخدمة: الصلب الكربوني، الصلب الصلب الخفيف، الصلب الناعم، الفولاذ المقاوم للصدأ،

الألمنيوم، السبائك، النحاس، البرونز وغيرها.

2. الأشكال المناسبة للأنابيب: أنابيب، قضبان صلبة، مربعة، مستطيلة، بيضاوية، ملفات وغيرها

3. يتم التحكم بها من خلال PLC ولها وظائف يدوية، شبه أوتوماتيكية وأوتوماتيكية بالكامل

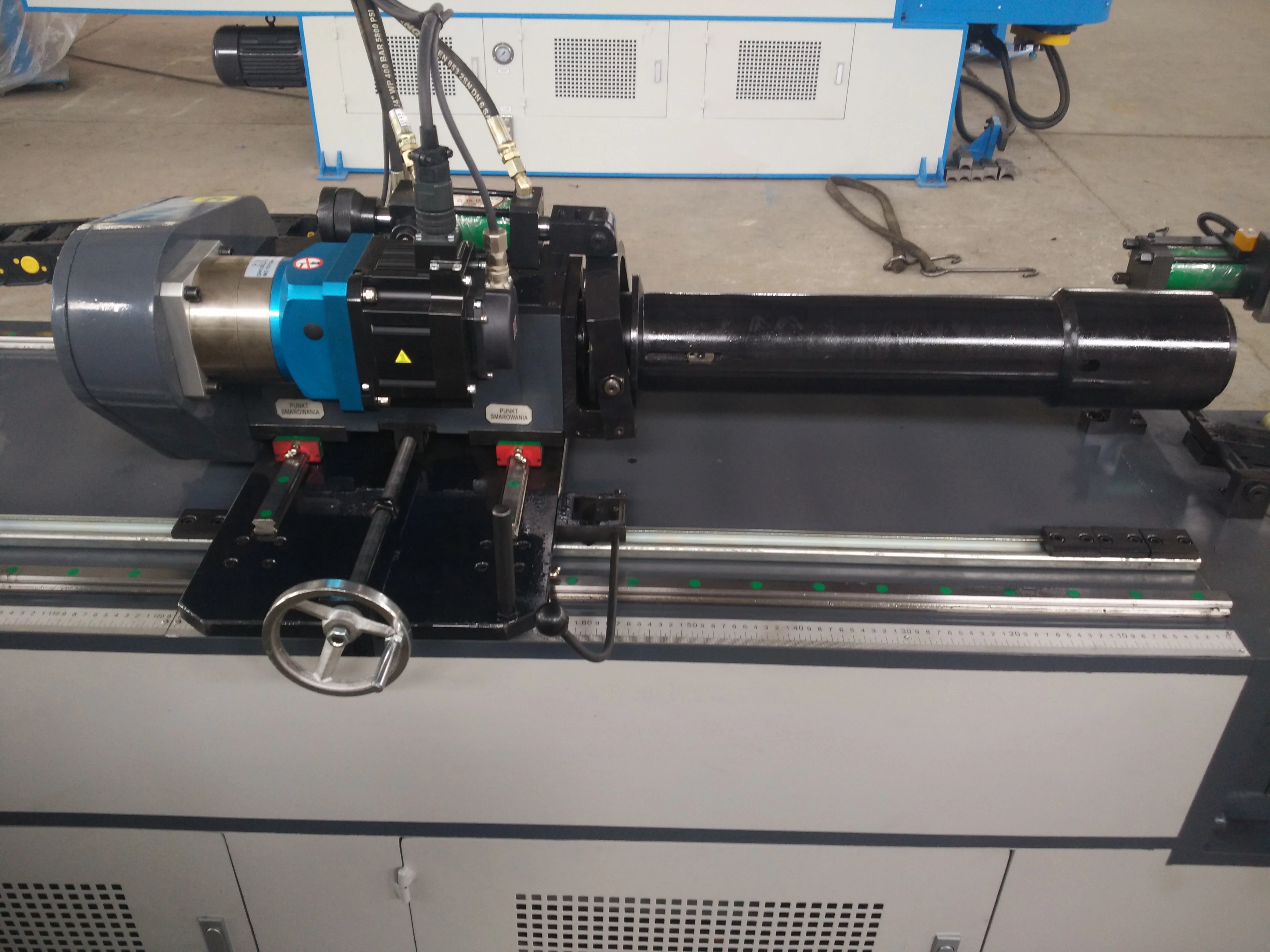

4. يضمن المحرك العاقد الدوران التحكم في الثني الثلاثي الأبعاد وكفاءة العمل

5. مجهزة بآلة قبض الهيدروليكية لأنابيب التحكم، مع دقة زاوية الانحناء التي تتحكم بها الوحدة المشفرة بمقدار 0.1 درجة تقريبًا

6. يمكن إدخال حوالي 200 برنامج إلى وحدة التحكم PLC، ثم يتم عرضها على شاشة التشغيل التفاعلية شاشة لمس سهلة التعلم والفهم

7. توفر شاشة اللمس بلغات مختلفة حسب الطلب

8. استخدام صمامات هيدروليكية ولوحات الزيت يمكن أن يتحكم في الحركات بشكل فردي لتمديد عمر الأجزاء الهيدروليكية

9. وحدة التوجيه تحتوي على وظيفة المساعدة في الدفع وفي نفس الوقت تمتلك وظائف التكرار والدخول المتكرر التي يمكن أن تجعل طول وحدة الإرشاد أقصر

10. وظيفة العد يمكنها عد كمية قطع العمل بدقة وحفظ البيانات سواء في تشغيل أو إطفاء الجهاز

11. نظام윤滑 تلقائي لحماية المكونات وتحسين عمر عمل الآلة;

12. تحتوي على وظيفة الكشف التلقائي عن الأخطاء ووظيفة الحماية المحدودة، وإزالة أو تغيير الأعطال بسهولة وسرعة

13. مفتاح القدم القابل للحركة مع وظائف البدء التلقائي، والإيقاف المؤقت، والطوارئ-توضيح، آمنة ومريحة.

14. الوظيفة الاختيارية لعكس النواة ببطء

15. الوظيفة الاختيارية للثني البطيء

16. وظيفة اختيارية لاستخراج النواة المُتوقَّع.

تكوين نظام التحكم الهيدروليكي والإلكتروني

|

الاسم

|

الشركة المصنعة

|

|

المحرك الهيدروليكي

|

سوتشو رونمالى

|

|

مضخة هيدروليكية

|

ووشي تولى

|

|

صمام هيدروليكي

|

يوتشي يوكن

|

|

لوحة طريق الزيت

|

سوتشو بو غوان

|

|

أسطوانة

|

شنغهاي تشي فان

|

|

أنبوب الزيت

|

سوتشو كيجيا

|

|

شاشة تعمل باللمس

|

تايوان W إينفيو

|

|

PLC

|

اليابان ميتسوبيشي

|

|

جهاز التحكم بالزاوية

|

اليابان نيميكون

|

|

تبديل الطاقة

|

وينتشو تشانغشينغ

|

|

الجهاز المتواصل

|

الألمانية SCHNEIDER

|

|

أجزاء كهربائية أخرى

|

ألمانيا شنايدر، أومرون , تايوان شيلين

|

التكوين أعلاه هو النوع الشائع لـ CNC-2A-1S، والذي يمكن تجهيزه أيضًا

مع العلامة التجارية المحددة من قبل العملاء

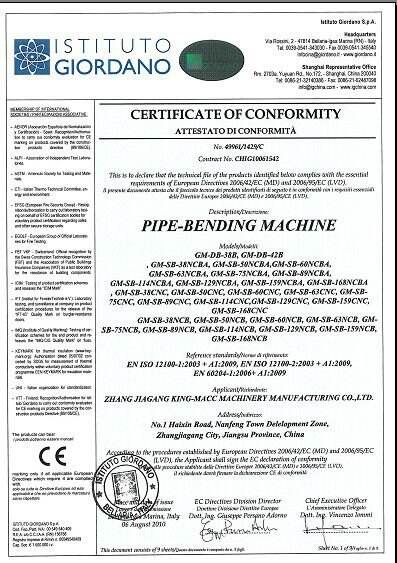

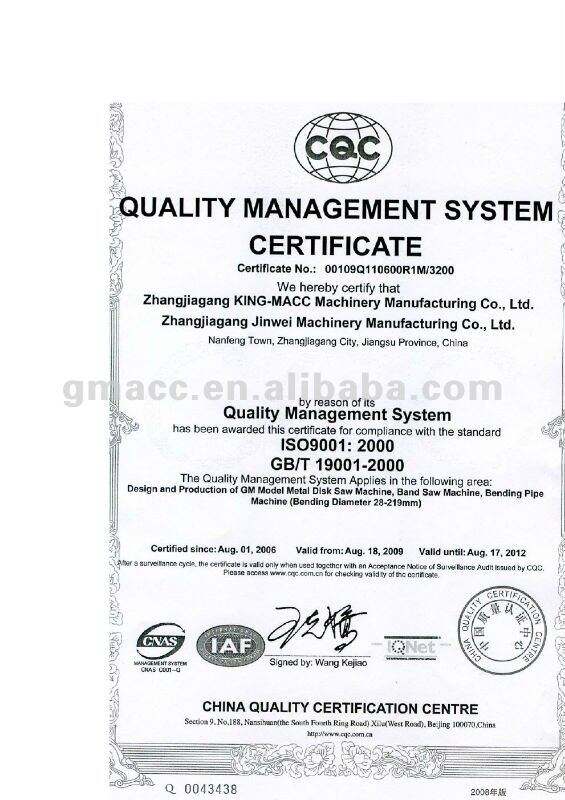

Zhangjiagang King-Macc Machinery Manufacturing Co., Ltd

خدماتنا

1) المراقبة والاختبار

بعد استلامنا لوديعة أولية قدرها 30٪، سنبدأ في الإنتاج. عندما تكتمل الآلة، يأتي المشترون لمراقبة واختبار الآلة بأنفسهم، حتى إذا كانت الآلة تلبي رضا المشترين، يمكنهم دفع الـ 70٪ المتبقية من المبلغ

2) الوثائق الفنية

يجب على البائع تزويدها المشتري بالوثائق اللازمة للتركيب والتشغيل خلال 5 أيام بعد توقيع العقد، وسيتم تقديم الوثائق الأخرى ذات الصلة للمشتري قبل الشحن

3) خدمة ما بعد البيع

ستقوم الخدمة ما بعد البيع من قِبل البائع. سيوفر البائع جميع أنواع الدعم الفني للمشتري مجانًا عبر الهاتف أو الفاكس أو البريد الإلكتروني. وبعد انتهاء فترة الضمان لمدة سنة واحدة، نضمن لك الصيانة مدى الحياة

4) التركيب

نقدم لك خرائط التحكم الكهربائية وكتيب التعليمات لتركيبها مع تعليمات باللغة الإنجليزية. إذا كان هناك طلب، يمكننا إرسال 1 أو 2 مهندسين إلى بلد المشتري للاستكمال التركيب والتدريب

GMACC

آلة ثني الأنابيب المعدنية الهيدروليكية عالية الدقة لمعدات البناء هي حقًا منتج رائد من GMACC، تم تطويره لتقديم دقة لا مثيل لها في ثني الأنابيب. وقد تم تطوير هذه الآلة خصيصًا لثني أنابيب الفولاذ المستخدمة في تصنيع عربات الحمل، مما يوفر حلًا بسيطًا وكفؤًا وموثوقًا للمحلات الصغيرة والمتوسطة.

يقدم الأداء بسرعة عالية وضمان شركات التأمين أن يكون الشخص المستخدم ودوداً، مما يسمح للمشغلين بالعمل بكفاءة وفعالية. القدرة على الانحناء من 6 مم إلى 63 مم في القطر، مع وجود زاوية انحناء قصوى بالدرجات. مصنوع باستخدام أنظمة هيدروليكية متقدمة والتي ستصنع ضغطًا عاليًا مع ضوضاء أقل لضمان إجراء سلس وهادئ.

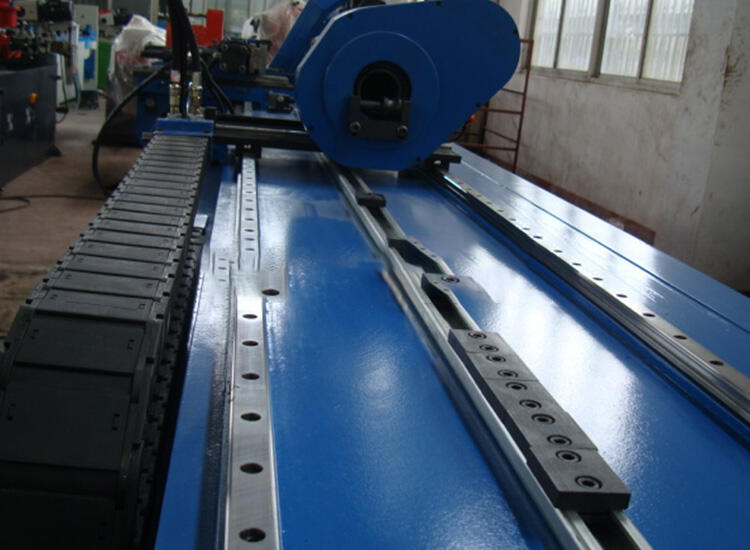

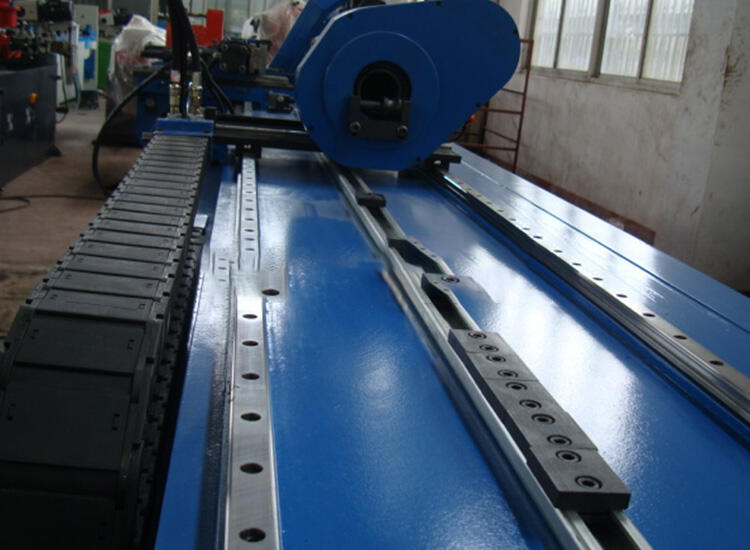

التقنية المتقدمة للعتاد الانحنائي تتأكد من أنها تعمل بدقة قصوى. هذه الأجهزة تستخدم دعائم خطية دقيقة للعربة، مما يضمن أن الانحناء يحدث حيث يجب أن يكون. تحتوي على نظام محاكاة ثلاثية الأبعاد يسمح للمشغلين بإنشاء تسلسل انحناء دقيق ومحاكاة عملية الانحناء قبل ثني الأنابيب الفعلية.

يتميز بشاشة تحكم حسية CNC، مما يسمح للمشغل بتغيير الزاوية ومدة انحناء الأنبوب، مما يضمن أن الأنبوب المنحني يلبي المواصفات الدقيقة المطلوبة. نظام التحكم سهل الاستخدام، حيث يوجد مجموعة من البرامج المثبتة مسبقًا والتي يمكن الوصول إليها بسرعة.

مصنوع من مواد عالية الجودة مثل سبائك الألومنيوم والبناء الكربوني ألياف مركبة. متين وخفيف الوزن، مما يجعل من السهل نقله واستخدامه. تحتوي آلة ثني الأنابيب على طاقة هيدروليكية تمكنها من العمل تحت مجموعة متنوعة من قدرات الحمل، مما يوفر مرونة لتطبيقات مختلفة لثني الأنابيب.

جهاز ثني الأنابيب المعدنية بدقة عالية باستخدام الطاقة الهيدروليكية لمعدات عربة اليد من GMACC هو ضرورة لأي صانع يرغب في تحسين عملية الإنتاج الخاصة به.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW